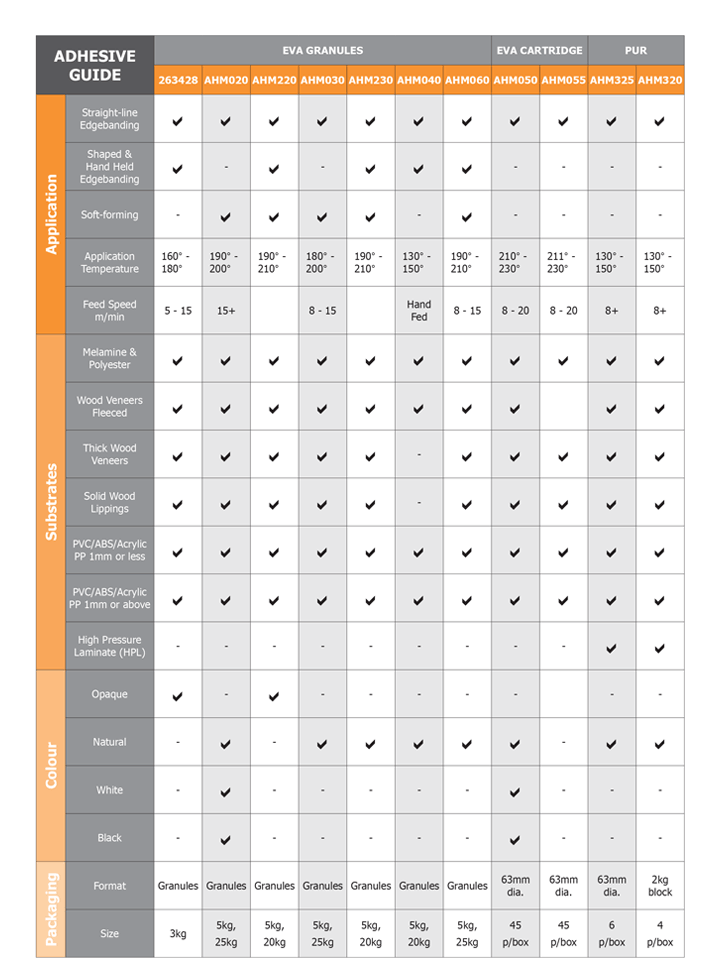

All NEY Hot Melt (EVA) adhesives for edgebanders are specially formulated exclusively for ourselves by some of the most eminent chemists in the industry. Feed speeds, viscosity, open time and application method all contribute to the quality of the bond and its aesthetic appearance. There is no such thing as “one size fits all”.

With all our experience in this field we are able to recommend precisely the glue that should be used on any given machine. It is false economy just to select an EVA based on price. |

The cheaper glues have less adhesive strength and contain more filler content which can burn or cook brown in the pot causing poor adhesion, an unsightly glue line and regular expensive maintenance costs to clean or repair the gluepot. Not to mention the additional time spent cleaning the panel.

The table below gives a good guide as to what adhesive to use, but please do not hesitate to contact our product speacialists for any further information.

|