|

Machinery - Foil Coating & Pressing |

NEY offer three different solutions, each having its own position in the market.

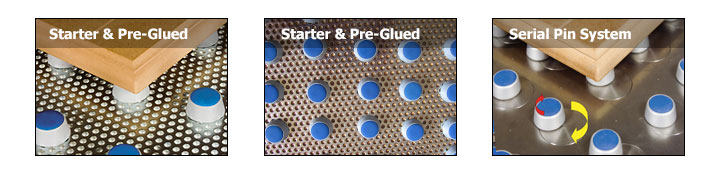

One of the downsides of membrane pressing can be the number of jig boards required to suit different sized components. This is particularly an issue for manufacturers working on a just in time basis or producing bespoke sizes as the time spent preparing or changing jig boards soon becomes disproportionate reducing the number of press cycles achieved. The introduction of movable pins does away with the need for panel jigs and allows the table to be rearranged for different loadings very rapidly. This not only speeds up production, increasing the number of cycles that can be achieved but also clears the area around the press improving tidiness and operator safety.

Starter System: Designed for use with unglued foils.

The name really doesn't do this product justice. It is really an expandable system that can be added to by increasing the number of pins as production grows. The system consists of a perforated steel base panel which sits in the press to take individual magnetic pins which can be positioned or removed to suit different loading patterns. The base panel can be supplied to suit the dimensions of any press.

Pre-glued System: Can also be used with unglued material.

For this application the base panel is a solid sheet which is Teflon coated to prevent the adhesion of the PVC foil to the machine. The pins are again individual items which can be removed or relocated but their unique ergonomic design ensures that they are easily released from the pre-glued material.

Serial Pin System: Suitable for unglued foil only.

This is the more sophisticated system whereby the pins are positioned within the base panel. Each pin is attached in an off centre position on a rotating disc allowing them to be individually moved in a wide arc and positioned to suit the panels to be pressed. The pins remain permanently attached to the system making them suitable for higher volume situations where the loading ratio of each pressing is maximised. The size of the panels are manufactured to suit your individual press.

The name really doesn't do this product justice. It is really an expandable system that can be added to by increasing the number of pins as production grows. The system consists of a perforated steel base panel which sits in the press to take individual magnetic pins which can be positioned or removed to suit different loading patterns. The base panel can be supplied to suit the dimensions of any press.

Pre-glued System: Can also be used with unglued material.

For this application the base panel is a solid sheet which is Teflon coated to prevent the adhesion of the PVC foil to the machine. The pins are again individual items which can be removed or relocated but their unique ergonomic design ensures that they are easily released from the pre-glued material.

Serial Pin System: Suitable for unglued foil only.

This is the more sophisticated system whereby the pins are positioned within the base panel. Each pin is attached in an off centre position on a rotating disc allowing them to be individually moved in a wide arc and positioned to suit the panels to be pressed. The pins remain permanently attached to the system making them suitable for higher volume situations where the loading ratio of each pressing is maximised. The size of the panels are manufactured to suit your individual press.